Get the finest industrial heater technology from HCS for your operation. Select from a wide variety of heaters that are made for heating components and controlling manufacturing operations.

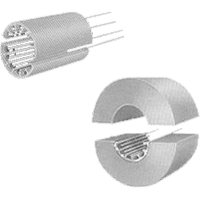

Aluminum cast-in heaters provide an efficient method of heating and controlling extruders, compression molding platens, heat sealers, and vacuum forming platens. Aluminum cast-in heaters give you accurate temperature control within plus or minus two degrees.

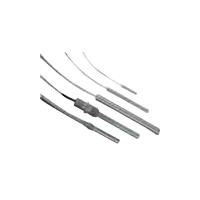

Cartridge heaters are available in various sizes from 1/8 inch to 1-1/4 inch in diameter to lengths that are only restricted by the diameter of the heater. Various lead styles are available to withstand constant flexing, wash-down, or extremely corrosive and moist environments.

Get ceramic band heaters to withstand high temperatures. These units are long-lasting and now available with 1 /4 inch or 1 /2 inch insulation. Ceramic band heaters are available with high-velocity fans and can be used as efficient heating or cooling bands that provide accurate temperatures.

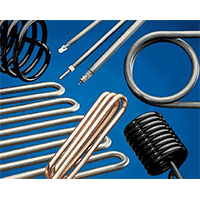

Do you require high temperatures in a confined space? A coil and cable heater may be the best choice and can be used in a variety of applications and also in areas where the heaters need to be formed in irregular shapes and sizes.

Hard ceramic heaters are used where extreme temperatures are required. Hard ceramic heaters are capable of temperatures of 1200°C or 2200°F. These heaters are made with a hard ceramic shell and have a Kanthal or Nichrome wire that is first coiled and then placed in a groove.

Order these heaters in various sizes, voltages, and wattages to suit every application. Mica and mineral band heaters are used when temperatures up to 900°F are required. Mineral insulated band heaters are used for temperatures to 1400°F.

Mica strip heaters are available in a number of constructions depending on the material to be heated and the application. Sheath temperatures are typically 700°F to 1400°F, depending on construction, watt density, sheath material, and type of insulation used.